5 Simple Ways Sustainable Businesses Cut Energy Costs

High overhead costs are burdensome for businesses that survive on slim margins. As supply chain problems and rising inflation result in unexpected operational cost increases, it’s more important than ever that business owners pay attention to their utility bills and seek out opportunities to cut down on energy usage.

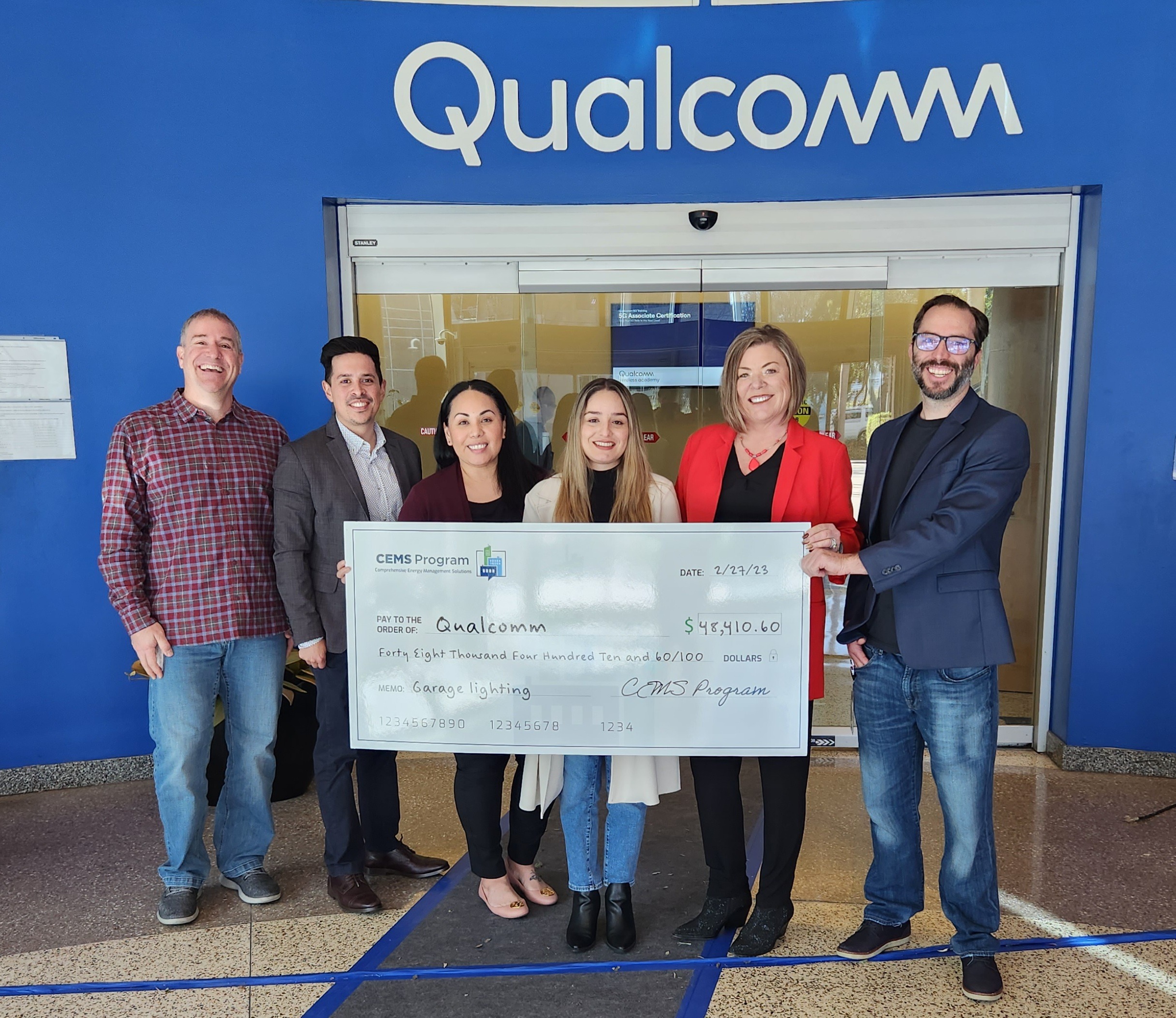

To promote energy efficiency and inspire businesses to take on projects that reduce their carbon footprint, the Comprehensive Energy Management Solutions (CEMS) program held a webinar outlining the top five biggest sources of wasted energy and how to combat them.

What follows is a summary of the presentation.

1. Decrease lighting costs with new bulbs and automated controls

Businesses often find that low-effort updates to existing light fixtures produce real savings without major upfront costs. For example, you can easily swap fluorescent linear tubes for LEDs without replacing your existing fixtures. Lighting controls like occupancy sensors and timers can help your business minimize energy waste through automation. Occupancy sensors automatically turn the lights on when there are people present and turn lights off when no motion is detected.

2. Optimize HVAC efficiency with routine cleanings

It takes a lot of energy to heat, cool and ventilate. For most businesses, the HVAC system requires more energy to operate than any other piece of equipment or appliance. Older HVAC units in poor condition can waste energy. Cleaning condenser coils and replacing air filters are two ways businesses can improve performance. Upgrading to a new model designed with energy efficiency in mind will also result in lower utility costs and improved occupant comfort.

3. Keep display cases cool and costs low with anti-sweat heater (ASH) control systems

Anti-sweat heaters protect refrigerated display cases from unsightly frost and damaging ice build-up. But when left uncontrolled, ASHs operate non-stop, consuming a lot of energy along the way. ASH control systems ensure that refrigerators run only when necessary—keeping display cases clear and ice buildup down at a fraction of the energy cost.

4. Upgrade to an electric, heat pump water heater

Conventional water heaters, whether gas or electric, require large amounts of energy to generate heat. Instead of generating heat directly, heat pump water heaters draw existing heat from the space around the unit to warm water in storage tanks. Businesses immediately notice the savings when they switch from tankless, gas-powered water heaters to electric, heat pump water heaters. Many business owners and managers discover the money they save over time more than covers the higher price tag on these more efficient models.

5. Cut costs and keep staff safe with food service equipment upgrades

Restaurants rely on a variety of equipment and appliances to prepare food providing many opportunities to save energy. Encourage your staff to turn equipment off when it’s not in use. Idling equipment quietly consumes unnecessary energy that increases overhead. Keeping your kitchen ventilation hoods clean can also help. Accumulated grease and grime force the systems to work harder, and unmaintained kitchen ventilation hoods are more likely to malfunction and put staff in danger. Regular cleanings and status checks will help keep this crucial piece of equipment running efficiently and safely.

Incentives from CEMS can help businesses save both energy and money. Visit our incentives page to learn more about available incentives to make buying energy-efficient equipment and upgrades more affordable.

Last Updated: October 11, 2022